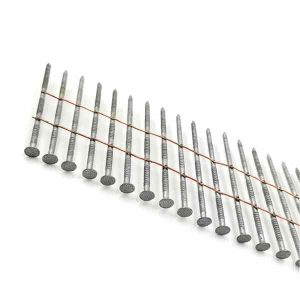

Galvanized Coil Framing Nails Smooth

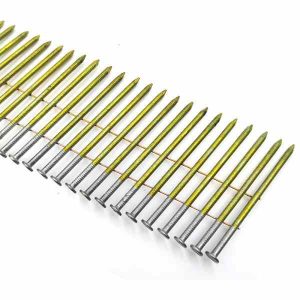

- Material: carbon steel, stainless steel.

- Diameter: 2.5–3.1 mm.

- Nail number: 120–350mm.

- Length: 19–100 mm.

- Collation type: wire.

- Collation angle: 15°.

- Shank type: smooth.

- Point: diamond, chisel, blunt, pointless, clinch-point.

- Surface treatment: electro – galvanized.

- Description

- Inquiry

Description

INTRODUCE————————————————————————————————————————————————–

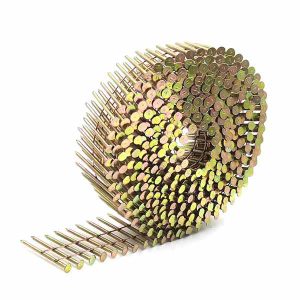

Galvanized coil framing nails is composed of a certain quantity of same shape nails with the same distance, connected by copper-plated steel wire, the connecting wire is in a direction of βangle with respect to the center line of each nail, then rolled in coil or bulks.Coil nails can save efforts and improve productivity greatly.

Main application fields include binding of pallet & crate, fencing, garden furniture and external cladding fixation, etc.

| Shank Dia | Length | Head Dia | PCS / Roll | |||

| Inch | mm | Inch | mm | Inch | mm | |

| 0.083” | 2.1 | 1-1/4”~2” | 32~50 | 3/16” | 4.7 | 400*40 |

| 0.090” | 2.3 | 1-1/2”~2-1/4” | 38~57 | 1/5” | 5.8 | 300*30 |

| 0.099” | 2.5 | 1-3/4”~2-1/2” | 45~64 | 1/4” | 6.3 | 300*30 |

| 0.113” | 2.87 | 1-1/4”~3” | 32~76 | 1/4” | 6.3 | 250*20 |

| 0.120” | 3.05 | 2-3/8”~3-3/4” | 60~95 | 9/32” | 7.1 | 200*20 |

| 0.131” | 3.33 | 3”~5” | 76~127 | 9/32” | 7.1 | 200*20 |

Galvanized Coil Framing Nails

TOOL————————————————————————————————————————————————————

Galvanized Coil Nails Will Fits All Standard Coil Nail Guns

ADVANTAGE————————————————————————————————————————————————

- Electro Galvanized fasteners have a very thin layer of Zinc that offers some corrosion protection.

- We need to produce using high-quality materials and ensure that galvanized capacities up to 40G/M2.such nails are rust and corrosion resistant

- Strict production process, high-quality raw materials, fine work. Advanced equipment, professional R & D team.

- We strive to build the huazhen brand, committed to drawing, galvanizing, developing one-stop production, layer control, IS09001 quality.

APPLICATION———————————————————————————————————————————————–

galvanized coil framing nails have a very thin zinc coating and are therefore appropriate for interior applications.Hot-dip galvanized coil nails are appropriate for any kind of mild-to-corrosive environment and provide long-term corrosion protection.

- Sheathing.

- Ply bracing.

- Fencing fixation.

- Timber & softer pine framing material.

- Composition roofing.

- Underlayments.

- Fiber cement boards.

- Cabinet and furniture frames

You can see some usage scenario in below picture.